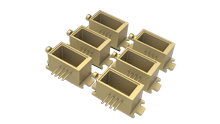

AlSiC Optoelectronic Housing

Optoelectronic module is consistently developing toward smaller; more integrated and more efficient orientation, resulting in more heat production and greater heat concentration. AlSiC material has a matched coefficient of thermal  expansion and still keep high thermal conductivity, coupled with its low cost, thus to provided the industry with a better package design option.

expansion and still keep high thermal conductivity, coupled with its low cost, thus to provided the industry with a better package design option.

Fadi Optoelectronic Housings is designed to host optoelectronic converter and codec. The housing consists of a AlSiC base plate and welded kovar walls, top cover is also kovar material. Optoelectronic module manufacturer can utilize this housing with better performance and lower cost without any change to their original manufacture facilities.

In comparison with traditional W-Cu base plate plus kovar wall assembly, AlSiC assembly has better thermal conductivity, better compactness, lower cost and lighter weight. W-Cu composite, from its hard manufacturing process view point, is unable to achieve perfect compactness on its products. More seriously, you can only find the defect after gold plating process or worse, after optoelectronic device welding is over, leaving 10% to 20% module wasted. AlSiC material is made from infiltration process, which guarantees the even and high density of the material. Replace W-Cu with AlSiC will dramatically save cost.