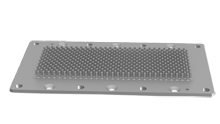

AlSiC IGBT Base Plates

Great amount of heat is produced when high current IGBT module, especially when current is over 600A, works. In the thermal management scheme of such modules, the main goal is to eliminate heat juncture. Heat dissipating passage between bottom of chip and heat dissipater needs to be designed as big as possible.

Great amount of heat is produced when high current IGBT module, especially when current is over 600A, works. In the thermal management scheme of such modules, the main goal is to eliminate heat juncture. Heat dissipating passage between bottom of chip and heat dissipater needs to be designed as big as possible.

Cu base plate has excellent heat conducting ability, but the CTE of Cu is almost triple that of IGBT chip. Further more, the IGBT substrates could be as large as 50mmX60mm, accentuating the triple difference. The triple CTE difference could be solved with DCB or multi-layer DCB when it is low current IGBT, but this method still does not cope with high current IGBT module. The solder layer between chip substrate and Cu base plate is doomed to be fatigue within 1000 heat cycle and lamination around solder border appears. In such circumstance, pressure contact mounting method is better than welding. But pressure contact mounted module, when used in vibration circumstances, like that of high speed rail,  electric car, plane, etc, its working reliability is awfully decreased. Now, what is the best way to securely package high power IGBT module to guarantee its reliable performance in vibration, high temperature and dust working circumstances?

electric car, plane, etc, its working reliability is awfully decreased. Now, what is the best way to securely package high power IGBT module to guarantee its reliable performance in vibration, high temperature and dust working circumstances?

The typical CTE of AlSiC material is 7~9ppm/℃, in reference, chip is 6 ppm/℃, in addition of the help of DCB, with the adoption of AlSiC IGBT base plates, the above mentioned triple CTE difference is eliminated naturally. And, the thermal conductivity of AlSiC material could be as high as 200~235W/mK (25℃), 50% higher than aluminum alloy.

AlSiC is light weight material, its weight is that 1/3 of Cu, much like aluminum, but its strength is comparable to steel. These characters make AlSiC even better material for anti-vibration utilization in comparison to Cu material. Thus, the unique combination of high TC, low CTE, high strength and light weight, makes AlSiC material unparallel in high power electronics package area.

Learn more: the dome shape of AlSiC IGBT base plates