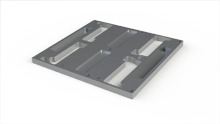

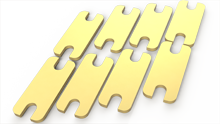

AlSiC Power Microwave Substrate

AlSiC is an ideal material for power microwave packaging. With the CTE zoomed in 7~8ppm/℃, AlSiC well matches the microwave device. Thermal stress compensation is not necessary. The thermal conductivity is as high as 200W/mK, therefore, increasing the system's total heat dissipation ability while keeping device in health condition.

AlSiC is an ideal material for power microwave packaging. With the CTE zoomed in 7~8ppm/℃, AlSiC well matches the microwave device. Thermal stress compensation is not necessary. The thermal conductivity is as high as 200W/mK, therefore, increasing the system's total heat dissipation ability while keeping device in health condition.

When in same shape and dimension, The weight of a AlSiC product is 1/3 of that of Cu, 1/5 of Mo-Cu, 1/6 of W-Cu. With the even better stiffness ratio, AlSiC is widely recognized in weight sensitive, reliability sensitive areas, like microwave  modules in aerospace.

modules in aerospace.

The cost of AlSiC material is lower than that of Mo-Cu and W-Cu, furthermore, the AlSiC can be built into complex shaped parts and large dimention parts, the other three AlSiC advantages that can not be overlooked.

AlSiC is a dense material, its hermetic statistic reaches beyond defense industry requirement: 1 x 10-9 Atm-cm3/sHe. When used as air tight package housing, a metal ring inside the upper top or kovar walls will be adopted to facilitate the cover welding.