What Exactly Is the Dome Shape On AlSiC IGBT Base Plate?

To understand this, we need to know how dome shape function.

One AlSiC IGBT base plate has upper side and bottom side. The upper side is flat, used to weld the chips’ substrate. The bottom side heat dissipation side, used to connect heat radiator.

How to connect? The radiator is pressed to bottom of base plate by screw bolt. Some customer used to put a piece of graphite paper between the base plate and radiator. And the connecting surface of radiator is quite flat, when pressed on the dome shaped bottom surface, the two surfaces would tightly connect together to enlarge the heat transfer tunnel.

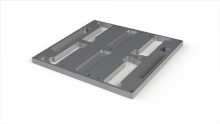

The dome shape is like the outer surface of a bended circular tube.

Some base plate suppliers carelessly produce the dome shaped surface to spherical surface, which is trouble saving practice and is wrong. Why?

For outer surface of a bended circular tube, the lengths of the curves on all the cross-sections parallel with X axis are same, same with Y axis. Thus, the press force is even on all part of base plate.

Situation is different with spherical surface, when a curve near X axis is closer, the curve radius is larger and the curve length is longer, vice versa. Same thing happen in Y axis direction. Result of this is that the connecting pressure on central part of base plate is lower than border, definitely is not what we want.

So, the dome shape must look like the outer surface of a bended circular tube, especially for large AlSiC IGBT base plate.