Welcome to Fadi Technology Co., Ltd., the leading AlSiC composite material products producer in China.

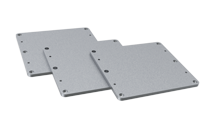

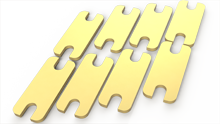

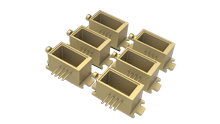

AlSiC (aluminum silicon carbide) IGBT base plates are essential parts of a high-speed rail. By combining ceramic and metal together, the AlSiC metal matrix composite is created, a new material actually resembling both. Featuring in high thermal conductivity ( TC ), low coefficient of thermal expansion (CTE ), high stiffness, light weight, AlSiC is an ideal material used for manufacturing power electronics base plates and substrates. The low CTE perfectly matches with that of electric chips'. The operation reliability of power module with AlSiC base plate is 10 times as high as that with Cu base plate.

AlSiC IGBT base plate is one of the key elements in high power IGBT modules that are widely used in high-speed rail driving, subway driving, new energy vehicle driving, wind turbine and welding robot. Photoelectric converter packaged with AlSiC, heat conducting effect is better than that of tungsten copper alloy, package weight is greatly reduced, and at the same time, reduces the cost. In fields like power electronics, power electronics, power microwave, photoelectric conversion, communication base station signal amplifier, CPU, LED, UPS, hybrid circuit etc., in comparison with traditional metal, ceramics and other packaging materials, AlSiC has unmatched performance advantage. AlSiC has also been widely used to make thermal-deformation-resisting structure parts, abrasion proof structure and lightweight aerospace structural parts.

Based on its advanced and reliable production equipment and process, quick responding market interfaces, Fadi Technology Co., Ltd. has accumulated a good reputation in the industry. We welcome you to contact us at any time on metal matrix composite technology and products.